Products

Security Products

IDenticard produces photo ID card systems that combine biometrics, digital imaging and other technologies to positively identify your people... access control systems that restrict entry into your buildings... and supplies and equipment that support these systems.

Most IDenticard customers are repeat buyers. Many have specified IDenticard products and services for decades.

ID Card Security

IDenticard offers a superior selection of ID card security features to protect your employees and your facility against the risk of fraudulent use and duplication of your ID cards. Our card security features can be used in any combination to provide exceptional protection for your security ID program. Most of our security features do not require special viewing devices or equipment. You can determine whether the ID card is authentic at a glance

Access Control Solutions

IDenticard access control systems restrict entry into your buildings, combine multiple card reader technologies, and positively identify your people. IDenticard partners with our customers to create access control systems that adapt to their changing security needs.

Photo ID Software

IDenticard's ID badge systems provide you with the flexibility and the security that you need in a photo ID card program. Unlike most badging programs, we don't lock you into a specific card type. Our systems offer you the choice of PVC or laminated polyester ... it depends on your preference and your requirements.

ID card systems simplify and speed security identification card issuing. The process begins by transferring ID data (for example, names, employee numbers and departments) into a computer. Next, a digital camera takes the photo. The badging software then combines an organization's logo, photo and ID data in a customer-specified badge format. Cardholder data stored in a PC or file server database can be used to develop security reports or in access control, data management, or similar systems.

RFID For Medical Implant

Strain for Medical Implant Manufacturers

Hospitals are increasingly shifting the onus to medical implant manufacturers and their distributors to sell on consignment and/or manage inventory on behalf of the hospital. When selling on consignment or through vendor managed inventory (VMI) programs, medical implant manufacturers and distributors experience common pains associated with manual, bar-code based inventory tracking methods:

Operation

- Inaccurate inventory / replenishment

- Higher inventory levels (to compensate for inaccuracies)

- Shrinkage

Sales / Service

- Significant time spent taking inventory and processing invoices / orders

- dissatisfaction due to stock-outs

Finance

- Higher working capital requirements

- Slow, inaccurate billing

- Delayed cash collection

AJNEYA Solutions for Consigned / Vendor Managed Inventory

AJNEYA provides an advanced solution, RFID Smart-Container and Mobile-RFID, which allow medical implant manufacturers and distributors to automate the inventory management process at customer sites.

Smart-Container

The RFID Smart-Container solution retrofits existing cabinets and shelves with a network-connected RFID reader sub-system that automates item-level tracking. The inventory process happens without field personnel involvement and can occur multiple times per day. Data is sent to back-end inventory management and billing applications in real-time via a wired or wireless network connection installed in the cabinet / shelf system. The solutions offer the ability to quickly and comprehensively authenticate inventory in the field based on digital signatures (i.e., to prevent counterfeiting) and programmable metadata such as manufacture date, manufacture site, lot number, and expiration date (i.e., for age-sensitive products).

Ajneya Solution Benefits

AJNEYA’s solutions for consigned / vendor managed inventory provide many compelling benefits:

Operation Efficiency

- Industry leading read accuracy for high confidence inventory counts

- Lower inventory levels (due to higher accuracy)

- Reduced shrinkage

Sales / Service Productivity

- Minimal time spent taking inventory and processing invoices / orders

- Increased customer satisfaction

Finance Optimization

- Lower working capital requirements (due to lower inventory)

- Accelerated, accurate billing

- Accelerated cash collection

RFID For Asset Tracking

RFID can be used to track more things than can be imagined, from tools to toilets and people to paintings. AJNEYA RFID can help you develop systems that can either track items from zone to zone or help you pin point specific location of items. You can now track or locate high priced or mission critical items anywhere, anytime using AJNEYA RFID’s diverse hardware and LocateWare™ RFID middleware.

Tracking and locating capability may be a security or health and safety requirement. AJNEYA RFID’s solutions satisfy the needs of a diverse community of users. Our full range of RFID readers, tags and software can be used to support first responders, secure parking areas, track admission to secure areas, track and locate critical assets such as computers, test equipment and life saving apparatus. Manufacturing is using RFID to track WIP (work in progress), semi-finished goods and finished goods. Transportation and logistics now have a cost-effective way of tracking goods in transit as well as the associated moving equipment itself.

AJNEYA RFID has watched the RFID landscape continually change and has kept pace with these changes by introducing an ever expanding portfolio of technologies to satisfy the broad variety of business requirements. AJNEYA RFID offers solutions that utilize low frequency (LF) and high frequency (HF) for the livestock tracking and monitoring industry. Access control solutions can require the rigid standards of HF or the flexibility of UHF (Ultra High Frequency) or active technology.

Valuable Assets:

RFID is being used to track and locate valuable assets such as computer and computer room equipment. Museums and art galleries are using RFID to track and secure valuable artefacts. RFID is being used to monitor continuous custody of critical or valuable items. Continuous and verified chain of custody is critical in a number of fields including law enforcement.

Manufacturing:

AJNEYA RFID is helping manufacturing to track WIP and assembly line components and tools. A manufacturer’s inability to locate semi-finished goods when required can severely impact productivity. Active RFID working in combination with LocateWare™ can eliminate hours of searching for tools and products. Active RFID is addressing the problems related to bulk storage and retrieval. When a traditional warehouse setup is not practical, active RFID can be the solution.

Healthcare:

Valuable and mission critical assets exist on many environments. Healthcare uses RFID to track and locate mission critical assets. Healthcare is also using RFID is improve patient bedside care protocols, establish safeguards for the tracking of movement of new born babies as well as safeguard the custody of senior patients. UHF combined with LocateWare™ is a cost effect way of tracking the movement of assets within an enterprise. Active technology combined with LocateWare™ can be used to locate assets within any monitors space, indoors or outdoors.

Security and Safety:

We live in a time of heightened security. RFID is being used to track items and people in and out of secure and sensitive areas. RFID is being used to monitor and control vehicle access and individual access to specified areas. AJNEYA RFID has a complete cross-section of RFID technologies that address virtually any security requirement and LocateWare™ software to provide reporting and accurate audit details for any environment. RFID is being used by first responders to track individual movement and locate valuable assets within a monitored area.

AJNEYA RFID has a full range of asset tracking solutions that can be customized for almost any need. LocateWare™ makes it easy to get an RFID installation operational quickly. LocateWare™ also makes it simple to get data from any RFID reader to most backend systems. When it comes to implementing an RFID solution you should do what you do best and turn to AJNEYA RFID for the rest.

Access Control and Identification

AJNEYA's RFID technology provides a hands-free access control solution with many advantages over traditional access control badges and systems.

With conventional systems, such as bar code, magnetic stripe, and proximity readers, user must handle the badge and place it close to (7-30 centimetres; 3-12 inches), or make physical contact with the reader. AJNEYA's unique RFID access control technology allows the user to enjoy complete hands free access control. Our access badge can be read up to 5 (~16 feet) meters from the RFID reader, which usually eliminates the need to handle the badge or walk very close to the reader. This freedom is particularly important to handicapped workers, when carrying packages, and during inclement weather.

To make installation simple, many models of AJNEYA's RFID readers can connect to the access control computer through wireless communications. This eliminates the need for long wiring runs and allows a reader to be easily re-positioned or moved as needs change.

The AJNEYA RFID access control system can report any unauthorized access and issue an alert to the host software. In addition, it can be used to trigger cameras and video recorders in order to capture unauthorized or authorized access in real-time.

Benefits of using AJNEYA RFID Systems:

- Provides an access control solution that is truly hands-free and unencumbered.

- Badges can be read up to 5 meters (~16 feet) from the access control doorway or portal.

- Allows reduced inventory-stocking levels.

- Installation is easy, thanks to the wireless communications between AJNEYA's RFID readers and the host computer

- Allows surveillance cameras and video recording equipment to be triggered when certain user-specified RFID events occur.

- AJNEYA's RFID tracker software allows RFID asset tags to be linked with the owner's access control badge to control movement of critical and high-value items into, out of, and within the facility.

Supply Chain Visibility

AJNEYA RFID active tags or transponders can be programmed with contents and assigned locations and then placed on containers and pallets that are stored in a warehouse. Additional information can be collected and added to the RFID tags or cards as the pallets move through the warehouse. The AJNEYA RFID tracking system can identify unscheduled movement, so managers and security can be alerted to possible theft.

AJNEYA RFID's automatic tracking system can identify and keep track of goods that are located anywhere in the warehouse or in any other part of the building where an AJNEYA RFID reader is installed. The amount of idle inventory tied up in storage can be greatly reduced through effective use of the information provided by the system.

The AJNEYA RFID system can also reduce theft and other forms of inventory shrinkage by immediately alerting the operations manager when a product is moved from its assigned area.

AJNEYA RFID solutions can also reduce the time and cost for counting stock as it enters the warehouse by collecting the data automatically and virtually eliminating the need for manual intervention. Benefits of using AJNEYA RFID Systems include: tracking the location of pallets and containers within the warehouse, notify management and security when unscheduled movements occur and reduce costs and time for check-in and check-out as containers and pallets enter and leave the warehouse. The main benefits of using RFID in the supply chain come from improved inventory tracking, especially when the technologies capabilities are used to collect information and provide visibility in environments where tracking was not done before. Manufacturers, distributors, logistics providers and retailers can each use RFID for inventory applications and, in carefully planned systems, may share the same tags to reduce implementation costs.

Because it can be read through packaging, without concern to orientation, without direct line of sight between object and reader and can withstand exposure to dirt, heat, moisture and contaminants that make bar codes unusable, RFID can remove blind spots from inventory and supply chain operations. By using the high accuracy, real-time and unattended monitoring capability of RFID to track raw materials, work-in-process and finished goods, inventory manufacturers can confidently improve visibility of their inventory to enable overall inventory levels, labour costs and safety stocks to be reduced.

RFID readers or interrogators, covering warehouse racks, shelves and other storage locations, will automatically record the removal of items and update inventory records. If an item is misplaced or needed urgently to complete an order, fixed-position readers or a worker with a mobile computer and RFID reader can automatically search for the item by reading for its specific ID number. To secure inventory from theft and diversion, readers can be set to sound alarms or send notification if items are placed in unauthorized areas of the facility or removed from storage without prior approval.

An Auto-ID Centre study found consumer goods manufacturers would reduce shrink (inventory loss) by an estimated 10 percent by implementing secure storage areas. Direct store delivery (DSD) and other remote sales and service personnel can take advantage of RFID readers or interrogators integrated with mobile computers to quickly and accurately count inventory held in stores or in the vehicle. The automated counting would save significant time in the field, enabling representatives to visit more customers in a day. For field service applications, permanent asset tags applied to equipment could store its ID, configuration and service history information to ensure accurate and appropriate service is performed in the field where access to a central records database may be unavailable.

Warehouses and Distribution Centres (DC) are where everything comes together in the Supply Chain. Whether a product has been shipped half way around the world or manufactured in the same building, the DC is the hub of the distribution process for any successful supply chain network. Finished or work in process product or material can be misplaced, lost or become stale dated if processes are not in place to ensure prompt movement of product as required downstream. RFID is becoming a critical data collection tool to ensure product visibility is maintained through the warehouse link of the supply chain.

RFID Solutions for Healthcare Industry

RFID has made its way into almost all the day to day operations of a Healthcare facility. Let’s take a look at these areas and see how the different RFID technologies are being used and why

Patient tracking

RFID is being used to track and authenticate patients, from new born babies to seniors suffering from dementia and everything in between. The technologies that are being used for patient tracking include almost all the RFID technologies. LF and HF are used for applications such as bedside care and mother and baby matching. UHF is being used to monitor patient movement and establish geo-fencing as required. Active technology is a more robust form of movement and motion tracking.

Wait Time Monitoring

RFID technology is being deployed to monitor patient wait times in real time. Reusable active technology let’s an ER see exactly the number of patients in the queue and length of wait time by patient.

Medication Authentication and Control

Bedside care has leap frogged the use of bar codes and embraced RFID to ensure the right medication is given to the right patient. Nursing staff find RFID easier to work with than bar codes and realize the additional privacy that RFID brings to the process. For example, when the nurse is away from the computer on wheels (COW) administering medication to a patient the computer can be programmed to go into screen save mode thus maintaining patient information confidentiality. Bedside care RFID typically employs contact like HF technology. Nurses or meds administrators can be virtually tethered to the COW using UHF technology.

Surgery Asset Management

The use of RFID is reducing the chance of overlooking things like sponges or other surgical kit components after an OR procedure. Many ORs are using LF technology to tag everything used in a surgery. Once the procedure has been completed the patient is scanned to make nothing has been left behind.

Asset Management

By using RFID to tag high demand items like pumps may institutions have reported fewer shortages of these critical items when required and less time lost searching for these items. By using UHF technology any critical piece of equipment can be tagged and tracked throughout a facility making them easy to locate when required. Asset tracking saves valuable people time as well as valuable capital funds.

Access Control

RFID is used by many establishments to control access to restricted entry and exit points as well as restricted areas within a facility. The most commonly used technologies are LF (Low Frequency) or HF because they are contact like and allow facilities to maintain a high degree selective security. Unmanned, controlled access security provides the audit trail information required for restricted access areas.

Laundry Management

Whether the laundry service is outsourced or in-house RFID is being used to manage this massive and essential service. Healthcare facilities use 100s of thousands of garments. The logistics of cleaning, ironing, folding, shipping and storing laundered items would be unmanageable without RFID. Early RFID laundry applications used HF technology which is slowly being replaced by UHF technology because of read distance being greater and tag costs being lower.

RFID in Schools

Traditionally, Parents always have been at the worrying edge concerning the safety of their children en-route to school, and the Schools always has the responsibility to transport the students to and from their respective homes. Problem in teachers and parents communication; Problem in providing Information to parent that their children have safely arrived or left school. The use of RFID helps reduce the concerns by automating the detection of entry/exit of children at the gates of the school.

The RFID solution

Parent can be informed, by sending message that their kids have safely arrived or left school gates.

Arriving:

Each student wears a tag with unique ID. When he enter the gate, reader nearby detect tag ID immediately and upload information to system to inform his/her parents via SMS or email.

Leaving:

When student leave school, the reader nearby detect tag ID immediately and upload information to system to inform his/her parents via SMS or email.

- Student attendance checking

- Students don't have to stop in queue, to slide card one by one. The system automatically records all attendance information.

- Builds a unique user-friendly messaging system, Teachers and parents can communicate conveniently

School notice:

Teachers can inform their parent about their meeting, payment, etc.

Student status notification:

Teachers send evaluation of students to their parent, such as behaviour in class, homework, behaviour comments, exam grades, recent status.

Even parents can send message to teachers in charge of class or school principals.

This solution can be scaled up to involve student tracking within the campus, such as visits to the Library, Play area, Food-court and other various internal facilities.

Tracking school staff such as janitors/housekeeping staff, teaching staff, etc can also be done to enable quick paging for emergencies etc.

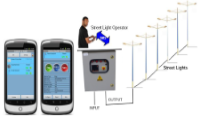

Street Light Management System

Street Light Management system (SLMS) is a simple, smart and very efficient way of operating and monitoring the street lights of the city. Through this system the street light operators can directly switch ON/OFF street lights from their mobile phones. Manual operation of street lights results in a huge amount of electricity wastage (over 3-4 hrs daily). This not only results in a heavy electricity bills but delay in switching ON the streetlights may also result in increase in thefts, road accidents. This versatile system can be used for many more applications depending on the ingenuity of the user. SLMS is an SMS based system through which operator can remotely monitor & control (Switch ON/OFF) a set of street lamps which were earlier being manually operated.

SLMS is completely wireless and easy to install thus the SLMS can easily be attached to the existing Street lights with minimal cost. The System being SMS based doesn’t require any additional investment for communication and can use the existing Mobile telephone network. SLMS is fully operable thru Android mobile phone.

The GSM - SMS based SLMS for operating and monitoring of the street lights is a unique versatile system. The SLMS along with a contactor of appropriate rating can switch ON/OFF a set of street lights. It works on 220V AC power and can control street lights of any Amperage. In case a contactor goes faulty the SLMS can detect it and inform the Street light operator as well as the central office for further actions. A maximum of 4 mobile handsets can operate/control this SLMS. The SLMS mobile application is a comprehensive application through which a detailed report can be generated and exported to a computer for further analysis.

Advantage:

- SLMS is a 3 Phase system.

- Automatic and manual operation mode.

- Protection against High/Low voltage, High/Low Current, Overload and short circuit, etc.

- Inbuilt 63 Amp Contactor.

- Remotely Configurable Timers and Multiple timer support.

- SLMS Mobile application for operations and monitoring of the system.

- Auto Report Generation.

- Remote power consumption metering.

- Multi User operation & monitoring i.e. Up to a maximum of 4 separate users may operate/monitor the street lights.

- Monitoring Multiple Locations from Same Mobile Phone.

- Secured Authorized access i.e. Only Authorized users can access this system.

- Low Power Consumption – 4 watts at peak load.

- Illicit power usage detection and prevention.

- Industrial grade design and make.

- IP65 compliance.

- Working temperature range: -10 C to 50 C.

Pump Control and Monitoring System

Pump Control & Monitoring (PCMS) is a simple, smart and very efficient way of operating and monitoring the water pumps. Through this system the pump operators can directly switch ON/OFF pumps from their mobile phones. Manual operation of street lights results in a huge amount of electricity wastage (over 3-4 hrs daily). This versatile system can be used for many more applications depending on the ingenuity of the user. PCMS is an SMS/Call based system through which operator can remotely monitor & control (Switch ON/OFF) water pumps which were earlier being manually operated.

PCMS is completely wireless and easy to install thus the PCMS can easily be attached to the existing water pumps with minimal cost. The System being SMS based doesn’t require any additional investment for communication and can use the existing Mobile telephone network. PCMS is fully operable thru Android mobile phone. The GSM - SMS based PCMS for operating and monitoring of the water pumps is a unique versatile system. The PCMS along with a contactor of appropriate rating can switch ON/OFF a water pump. It works on 220V AC power and can control water pumps of any Amperage. In case a contactor goes faulty the PCMS can detect it and inform the water pump operator as well as the central office for further actions. A maximum of 4 mobile handsets can operate/control this PCMS. The PCMS mobile application is a comprehensive application through which a detailed report can be generated and exported to a computer for further analysis.Advantage:

- PCMS is a 3 Phase system.

- Automatic and manual operation mode.

- Protection against High/Low voltage, High/Low Current, Overload and short circuit, Dry run, etc.

- Inbuilt 63 Amp Contactor/Relays.

- Remotely Configurable Timers and Multiple timer support.

- PCMS Mobile application for operations and monitoring of the system.

- Auto Report Generation.

- Remote power consumption metering, running time, water flow rate, etc.

- Multi User operation & monitoring i.e. Up to a maximum of 4 separate users may operate/monitor the pumps.

- Monitoring Multiple Locations from Same Mobile Phone.

- Secured Authorized access i.e. only Authorized users can access this system.

- Low Power Consumption – 4 watts at peak load.

- Industrial grade design and make.

- IP65 compliance.

- Working temperature range: -10 C to 60 C.

RFID for Retail Industries

Auto-id has long been used to track and identify parts for car and truck assembly. The vehicle assembly industry realized early on the value of bar codes and recently RFID to ensure the right parts are in stock, ordered just in time and at station when required for the assembly process. Many auto parts are painted and technology was slow to come to these components of the process.

The paint processes for parts manufacturing has always be a challenge when attempting to adopt new technology. Paint and chemicals was always the enemy when using identification markings such as bar codes. Chemicals would remove bar codes and paint would cover them. And then there was the temperature, 215 °C or 419 °F. Along came RFID. RFID was a natural for paint applications. Specially constructed tags can withstand the high temperatures of the ovens and can also withstand the impact of preparatory chemicals. RFID, unlike bar codes do not require line of sight or visual readability. An RFID tag continues to work even when covered with multiple coats of paint. It is no wonder that RFID has moved into the paint shops around the world.

More retail operations are rolling out item-level RFID tagging. After many pilot programs the hard numbers are in, RFID reduces shrinkage, improves stock levels and decrease employee turnover. Studies show that same class stores using RFID are outperforming those not using the technology. In some recently documented cases RFID equipped stores are outperforming non-RFID stores two to one. Store operators that have been using RFID attribute improved stock levels and store performance to the technology. Many of these operators are reporting that the ROI on RFID is about six months.

The bottom line savings come from better inventory management and reduced shrinkage at those locations. Inventory management isn’t just about stocking the right levels and sizes of different SKUs on the floor. RFID lets the store know if the items are in the right place. A store that is better organized sells more products, has less stock outs and encounters less shrinkage. RFID technology helps retailers get and stay organized.

A retail RFID solution requires hardware, tags and readers, and software. The software most retailers would require would validate shipments, transfer product between stores, tracking inventory by store, manage fulfilment operations, manage back room and sales floor movement and tie into existing Point of sales systems. AJNEYA RFID has the industry’s largest selection of tags and readers to choose from and LocateWare™ software that can quickly turn on RFID for a retail operation.

RFID alone has not replaced traditional electronic article surveillance as a shrinkage solution. RFID tags are too easily masked and can circumvent most attempts to use RFID as an external theft deterrent. It has been reported that stores using a combination of EAS and RFID item level tagging have reduced shrinkage by as much as 75%.

RFID Application in Fleet Maintenance

Efficient fleet maintenance is absolutely necessary given today's high equipment costs and climbing operating expenses. Whether you are involved in LTL, cartage, courier, direct store delivery (DSD) or field service operations, an integrated and cost effective fleet maintenance program is a prerequisite to increased profitability.

An improperly designed maintenance program can result in:

- Project delays and cost over-runs

- Too much technology The wrong technology

- The wrong technology

- Prematurely obsolete proprietary solutions

Fleet Maintenance with RFID

AJNEYA RFID technology can address many of the on-going concerns that Fleet Managers deal with on a day-to-day basis. AJNEYA RFID provides a variety of solutions suitable for many fields, such as the commercial, government, and private sectors. Our approach is to use open standards RFID technology in a way that will maximize your fleet management resources. An AJNEYA RFID solution will not only help you grow your business, but will also prepare you to adopt future technologies easier. For example, by placing RFID tags on critical assets that require regular maintenance AJNEYA can develop a solution that will give you accurate maintenance and usage history as well as reduce parts inventory and eliminate obsolete parts. Service data can be recorded directly onto RFID tags. That way service history is readily available anywhere the fleet vehicle goes. In addition, once a vehicle is tagged its movements can be recorded anywhere in an RFID enabled yard or depot.

AJNEYA RFID benefits include:

- Fast and accurate check-in, fuelling, and weighing;

- Tire maintenance improvements;

- Locating and monitoring of vehicles within the RFID equipped zone (knowing accurately and in real-time which vehicles are in the compound and which vehicles are on the road);

- Automated record keeping of maintenance checks and repairs;

- Accurate coordination of preventative maintenance whether based on mileage driven or motor runtimes or a combination of both;

- Too much technology The wrong technology

- On-line access to logs of previous maintenance work;

- Automated inventory control and procurement of spare parts;

- Improved equipment utilization;

- Better use of labour pool;

- Minimize errors

AJNEYA RFID Fleet Maintenance Solutions include mobile and fixed scanners, mobile computers and radio frequency identification (RFID) systems, along with applications from industry-leading partners, to help you streamline your maintenance operations. By capturing, moving and managing vehicle data across your enterprise, our solutions reduce truck maintenance costs and optimize fleet utilization.

AJNEYA RFID technology will help reduce vehicle downtime by ensuring fixes are made only when necessary - rather than according to a pre-established plan, and therefore greatly increase overall efficiency of the fleet and profitability of your business.

Vehicle Tracking System

A vehicle tracking system combines the installation of an electronic device in a vehicle, or fleet of vehicles, with purpose-designed computer software at least at one operational base to enable the owner or a third party to track the vehicle's location, collecting data in the process from the field and deliver it to the base of operation. Modern vehicle tracking systems commonly use GPS or GLONASS technology for locating the vehicle, but other types of automatic vehicle location technology can also be used. Vehicle information can be viewed on electronic maps via the Internet or specialized software.

Typical Architecture

Major constituents of the GPS based tracking are:

-

GPS Tracking Device:

The Device Fits into the vehicle and captures the GPS location information apart from other vehicle information at regular intervals to a central server. The other vehicle information can include fuel amount, engine temperature, altitude, reverse geocoding, door open close, Tyre pressure, cut-offs fuel, turnoff ignition, turn on headlight, turn on taillight, battery status, GSM area code/cell code decoded, number of GPS satellites in view, glass open close, fuel amount, emergency button status, cumulative idling, computed odometer, engine RPM, Throttle position, engine RPM and a lot more. Capability of these devices actually decides the final capability of the whole tracking system.

GPS Tracking Server:

The tracking server has dual responsibility. First receiving data from the GPS tracking unit and securely storing it, and second serving this information on demand to the user. It is the intelligence, power and configuration of GPS tracking server, which culminates into usability and feature support.

User interface:

User interface determines how you will be able to access information, view vehicle data and elicit business important details from it. Most usable is the one that is web based and doesn't demand installation of custom software.

Features:

- View current position and status of vehicles

- Easily identify the nearest vehicle to a location

- Real time visibility of vehicle location

- A range of alarms and alerts

- Improved security and protection for drivers and vehicles

- Record out of hours / unauthorized vehicle use

Ajneya provide cost-effective Vehicle Tracking Solutions that demonstrate high return on investment. The advantage of Ajneya's tracking solution is that it can be easily customize to your specific needs without the expense of creating a completely bespoke solution. You can enjoy total visibility of your high-value assets and vehicles.

RFID Application

If you simply need to know where your assets are, then our RFID applications are for you. Designed with simplicity in mind, the web based asset application is very simple to use, but very powerful. The application is browser based thus you can view, edit, print from any computer or a GPS enabled mobile telephone as long as you have an Internet connection. With our web based application you don't have to worry about loading CD's, you don't have to worry about purchasing PC's to support the application, you don't have to worry about constantly "maintaining" databases, or updating the application across 20 or 30 PC's or hand-held PDA readers.

RFID and Barcodes for Web Based Asset Tracking

RFID tags can store a range of information from a serial number to several pages. Readers may be mobile so that they can be carried by hand, or they may be mounted on a post or overhead. Reader systems can also be built into the architecture of a cabinet, room or building.

RFID Applications That Fits Your Budget

Best part of all we have a variety of purchase programs including a "service" based program where our clients do not have to write a large check in order to use our RFID solution, but rather a very reasonable monthly, quarterly, or annually service fee. Lastly, we have found that with most clients they only need our RFID or barcoding hardware devices but once or twice per year, and thus no need to necessarily keep the equipment in the drawer for the rest of the year, hence we can supply the equipment on an as need basis.

Various features can be implemented into the AJNEYA software to provide the flexibility needed for your individual requirements:

- Fully automated shipping and receiving

- Real time inventory

- Real time to generate receiving documents

- Real time to generate shipping documents

- Automatically order products that are low in inventory

- Real time security

- Real time marketing information about different brand of products

RFID Inventory Control

In present time there are many companies who are using refined Warehouse Management Systems integrated with Supply Chain Systems, Enterprise Systems, and Electronic Data Interchange (EDI), the movement and tracking of goods through the manufacturing and supply chain process is still a complex process which is difficult to manage. In many instances, the goods being distributed to the retailer must go through one or more third party distribution processes, before they reach their final destination.

At present, most material tracking systems employ two-dimensional barcodes that must be close to and within the "line of sight" of the barcode reader. This requires manual scanning or a conveyor-like process to position the barcode and scanner. Barcodes can run the risk of getting wet or scratched due to mishandling or a harsh environment, which often prevents accurate reading by the scanner. Manual intervention is labour intensive, costly, and error-prone. In addition, scheduled scanning or manual methods cannot ensure the inventory remains up-to-date, due to oversights, errors, and internal shrinkage.

With our RFID solution, inventory can be updated in real time without product movement, scanning or human involvement. Our fully automated system allows inventory status to be determined and shipping & receiving documents to be generated automatically. The system could also trigger automatic orders for products that are low in inventory.

Advantage:

- Total asset visibility

- Full inventory history

- Reduced inventory-stocking levels

- Facilitating Just-in-Time deliveries

- Full process control for products in the facility

- Reduced lead-time and cross docking time

- Improved sort/pick rate

- Reduction is storage and shelf space

- Improved security, reduced errors and overall reduced cost of operations.

As in many other RFID solutions, there are primarily two different approaches to Warehouse Inventory Management; one, using passive RFID tags or transponders, and the other, active tags. Passive tags have no power source; however when a reader sends a single a magnetic coil inside the RFID tag is "powered" allowing the tag to transmit its information. Active tags on the other hand are battery powered and are able to transmit data directly to an RFID reader or interrogator. A variety of factors will impact the decision to utilize a specific tag type including environmental conditions, application, and required read accuracy.

The full solution for the Inventory tracking application will contain three main RFID components: RFID Tags or transponders, RFID Readers interrogators, and software to collect and manage the RFID data.

Container/ Pallet Tracking

AJNEYA RFID active tags can be programmed with contents and assigned locations and then placed on containers and pallets that are stored in a warehouse. Additional information can be collected and added to the RFID tags as the pallets move through the warehouse. Our tracking system can identify unscheduled movement, so managers and security can be alerted to possible theft.

AJNEYA RFID-based automatic tracking system can identify and keep track of goods that are located anywhere in the warehouse or in any other part of the building where an our reader is installed. The amount of idle inventory tied up in storage can be greatly reduced through effective use of the information provided by the system.

Our system can also reduce theft and other forms of inventory shrinkage by immediately alerting the operations manager when a product is moved from its assigned area.

AJNEYA RFID solutions can also reduce the time and cost for counting stock as it enters the warehouse by collecting the data automatically and virtually eliminating the need for manual intervention.

Benefits of using AJNEYA's RFID Systems:

- Track the location of pallets and containers within the warehouse.

- Notify management and security when unscheduled movements occur.

- Reduce costs and time for check-in and check-out as containers and pallets enter and leave the warehouse.

Airport and High Security

AJNEYA RFID access control and personnel tracking and location systems can help to assure the security of restricted areas in airports, such as flight lines, baggage handling areas, customs, employee lounges, and other sensitive areas. These techniques could also be applied at maritime ports, railway stations, and passenger bus terminals.

AJNEYA RFID systems can be used to track employee and passengers in real time. Unlike other access control systems, AJNEYA solutions are completely hands-free so they have minimal interference with the busy work schedules and flow of employees and passengers. Read on for some examples of how AJNEYA technology could be applied.

Increased Passenger Efficiency and Flow

One of the major problems now facing airports and other transportation providers is how to maintain a high level of security and safe environment, while not impeding the efficiency that passengers have always expected. AJNEYA's RFID technology can help solve this problem.

Travel providers can issue electronic tickets in the form of AJNEYA RFID tags. These tags could be provided in form factors such as a clip-on badge, wrist band, or badge with a necklace. The AJNEYA "ticket" could be programmed with passenger identification and flight information at the ticket counter or curb-side check-in. Passengers could then be restricted to the concourses and gate areas appropriate for their departure. At the gate, the RFID reader could be used in lieu of ticket collection to facilitate efficient walk-on boarding. The passenger database linked to the RFID reader could assure the correct person is allowed on-board.

Tamper Resistance

To prevent tampering after entering the "secure" environment, a tamper switch on the badge could identify if an employee and passenger removes the RFID badge. Removal could both send an alarm notification to the RFID reader and immediately alert security, or it could notify the security operator that the badge must be re-validated before passing the next RFID portal. This assures only authorized persons are granted access to the appropriate areas.

Benefits of using AJNEYA RFID Systems:

- Secure passenger concourses and boarding areas for only authorized passengers

- Secure restricted areas for only authorized employees

- Quickly locate employees in critical environments

- Streamline customer ticketing and boarding while maintaining a high level of security

- Badge tamper sensor identifies when badge is removed and possibly swapped among employees or passengers

RFID in Manufacturing

Manufacturers can track and record in-process assembly information into the RFID tag as an item progresses along the line. For example, as features are added to a personal computer assembly, they could be recorded on the tag. In this case, the tag would keep a current "inventory" of the PC's contents. The tag information could later be read to produce a shipping list and invoice. The tag could also remain with the item for later use by field personnel during installation and maintenance.

RFID solutions are ideal for manufacturers who build several products on a single production line, or manufacture complex or customized products. Assembly line personnel could use an RFID reader to verify which processes have been completed, to determine which inspections or tests are required and to automatically update the central production database. And production planners and inventory control personnel could use the RFID tags to automatically update the customer database and finished goods inventory, using an RFID reader and PC, rather than manually creating data entry sheets, which could introduce errors into the system.

Advantage:

- Maintains current item information on the tag - ideal for managing production of complex or customized products and assemblies, eliminates the need for separate paperwork on assembly status and content

- Can automatically notify the central product database when each process has been completed

- Field personnel could use RFID tag to determine product features, date of manufacture, revision levels, etc.

- Real-time tracking of inventory, part kits and sub-assemblies.

RFID in Vehicle Parking and Management

AJNEYA has developed a RFID parking access control system that can be implemented quickly and simply. This parking solution is ideal for apartments and condos, gated communities, business parking lots and garages, university parking areas and recreation operations from hotels to RV camps.

RFID Solutions for Parking Control

Specific details for the final RFID equipment are application dependant; however, a typical scenario would include AJNEYA RFID windshield tags and either RFID readers with a built in antenna a multi-port RFID reader. The parking solution also requires one or more RFID enabled parking barriers, wired or wireless IP networking, and, to complete the parking solution, AJNEYA's RFID Parking Control Software.

AJNEYA's parking solution enables you to operate an unattended parking barrier with controlled parking access privileges. The parking barriers come in various sizes. They can be one or two lane setups. They can be installed to handle one or two way traffic. By using RFID technology you can issue parking passes, either windshield type tags are RFID cards, which are specific to the user. These passes can be controlled to determine the type and time of access permitted and can be activated and deactivated remotely by the operator.

It is a jungle out there - an asphalt jungle. Parking lot operators, whether public or private, face a number of challenges such as:

- Accurately identify and authorize vehicle movement.

- Collect and record vehicle movement data.

- Analyze traffic patterns to maximize facility utilization.

- Increase security within the parking facility

- Manage staffing for peak traffic periods

- Relieve congestion

- Improve customer service

AJNEYA RFID's parking solution gives operators the ability to enhance parking control management systems by using RFID to help automate existing parking control systems or when planning new ones. The use of RFID tags, readers and antennas makes it easier to automate the 'in and out' privileges of parking subscribers. Private parking policies can be seamless integrated with public parking areas without increases in manpower. Security, critical in today's world, can be improved. Payment processes can be automated. Occupancy rates and dwell times can be instantly calculated. Intelligent parking systems help captures data required for capacity planning and understanding current facility utilization. The automation of in and out and payment eliminates the need for addition staffing as the facility grows. Automated entry and exit, automated payment and shorter queues equate to satisfied customers. Above all, these benefits will drive higher revenues.